THE LUCKIEST AIRPLANE ACCIDENT

Introduction to airplane accident

Airplane accidents have guided aviation to improve airplanes over time. The analysis of these catastrophic events revealed weaknesses in airplanes design and gave a better understanding of the phenomenona that can lead to airplane accident.

For this reason, each airplane accident had a key role in regulamentations (FFAR) updates and design choices, to make the probability of an airplane accident extremely remote.

In this article, I will present one of the most famous airplane accident with an incredible lucky end.

The luckiest airplane accident: Boeing 737, Aloha Airlines 243

The Boeing 737 of Aloha Airlines 243 flight, 28 April 1988 is the most famous airplane accident in the history of Aeronautics. The accident happened at an altitude of 7300m

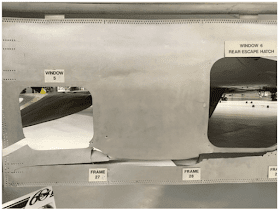

An entire part of the fuselage was lost due to a crack propagated from fatigue loads (cyclic loads) generated by pressurization cycles, the so-called GAG (Ground-Air-Ground) cycles.

The fracture was born into the fuselage upper panels, in correspondence of the junction rivets. The panels did undergo deterioration of structural performance due to corrosion, not identified. Indeed, the airplane used to park in maritime airports in Hawaii Islands.

The airplane incredibly succeeded in landing and only one member of the crew lost his life. That's why this is the most famous and lucky airplane accident.

The cause of the airplane accident: corrosion

Corrosion is a chemical phenomenon generated by the exposure of a metal (in this case Aluminium alloy) to atmospheric oxygen. The atoms of the metal surface react with the oxygen ones, creating chemical bonds and forming metal oxide. For example. rust is the result of iron oxidation.

The consequence is a change of physical and chemical properties of the material and a deterioration of mechanical properties. As a result, material strength decreases.

Due to this strength decay, a fracture occurred into the fuselage panels, leading to the aeroplane accident.

What fed the airplane accident: GAG cycles

What GAG cycles are?

To better understand how Ground-Air-Ground cycles work, I will make an example representing a normal airplane fuselage during a flight, explaining how the fuselage is loaded when the airplane changes its altitude.

The internal part of the fuselage, namely, the cabin, is taken under pressure. This is necessary since when we go up to higher altitudes, the atmospheric pressure decreases. Once we overpass a certain altitude, called Death Zone and corresponding to 8000 m, atmospherical oxygen pressure is too low to permit our lungs to inhale it and so respiration isn't possible.

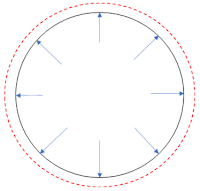

Let sketch the front view of a fuselage in the initial state, when the airplane is on the airport track, on the ground.

When the airplane takes off increasing the altitude, the external atmospheric pressure decreases. The internal part of the fuselage is taken to a higher pressure to allow the passenger and the crew respiration. So, the pressure on the inner part of the fuselage is greater than the pressure on the outer part. The result is that the fuselage walls are pushed outward, exactly as it happens when we blow up a balloon.

When the airplane climbs down to approach the landing, the external pressure increases and the fuselage panels come back to the initial position.

This cycle repeats at each travel, fatiguing the fuselage structure. Once a certain number of cycles is reached, the structure breaks. Of course, a fuselage is designed to withstand along with the entire life of the airplane with a large safety margin. For this reason, fatigue is one of the most important constraints to be taken into account during the design of a fuselage.

In this case, these cycles continuously stressed the fuselage panels, concentrating the stress on the holes where rivets were positioned, making the fracture grow up until a rupture and consequently the airplane accident occurred.

Lesson learnt from this airplane accident

The first lesson learnt from this airplane accident is that corrosion deserves very high attention, requiring inspection techniques to be implemented to monitor such phenomenon and material condition.

Also, experimental tests show how some structural choices can increase the life of a component subjected to fatigue (cyclic) loads.

One of the most important lessons learnt is that sharp corners or holes with a small radius decrease the life of a component subjected to fatigue, namely, the component withstands a lower number of cycles before reaching the failure.

For this reason, airplane windows have smooth corners. Sharper corners decrease the life of the fuselage panels. The catastrophic Comet airplane accident in 1954 was the most resounding proof.

ScienceFull.

Comments

Post a Comment